TRIANGLE ACOUSTIC EXPERTISE

In search of the perfect sound

For 40 years, TRIANGLE has been designing and assembling its prestige loudspeakers in its Soissons workshop. A team of engineers works closely with the production unit, ensuring unrivalled manufacturing quality in line with precise, detailed specifications.

TRIANGLE's craftsmanship is based on long experience, some of our employees having worked here for over 35 years. The individual parts are meticulously inspected and then assembled, with the aim of achieving impeccable finish and acoustic quality.

Technical excellence

RESEARCH & DEVELOPMENT

For many years, TRIANGLE has been investing in the most advanced technologies to innovate and constantly improve its acoustic expertise. The Klippel system is used for loudspeaker design and simulation.

Modern prototyping tools such as 3D printers, the latest CAD software and the MLSSA and CLIO measurement systems enable us to put our research into practice. Numerous tests are carried out to define the best curves and select the best performing materials.

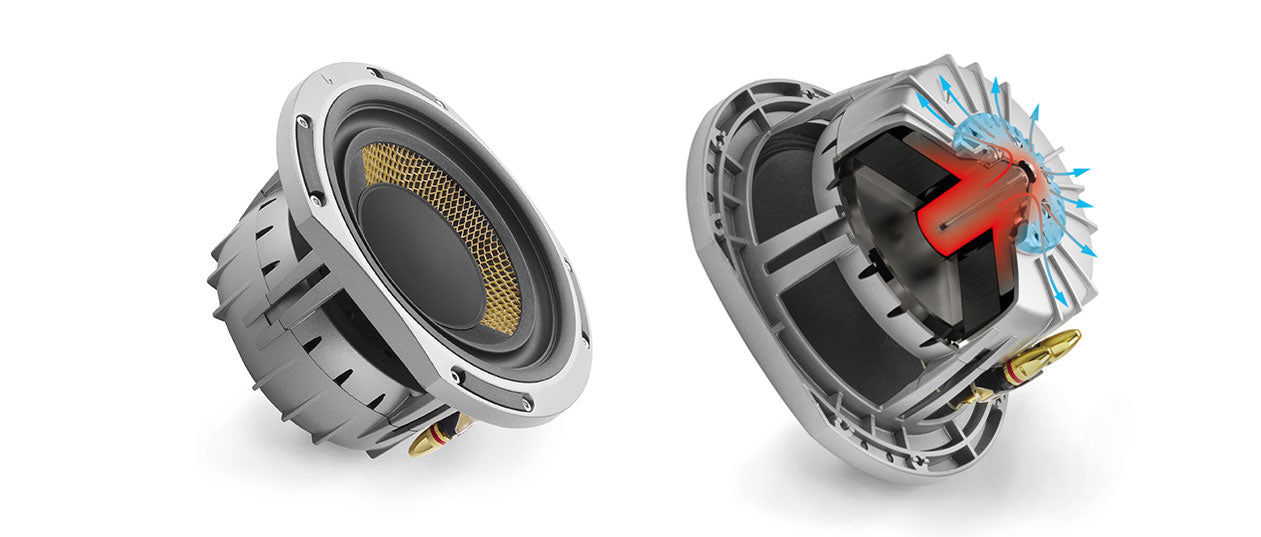

SPEAKER PRODUCTION

The prestige loudspeakers assembled in our Soissons production facility undergo strict controls at every stage to meet TRIANGLE quality standards.

Drastic checks to detect even the slightest imperfection, including centering and coil positioning, an auditory test to detect parasitic noise, and a final CLIO system check of the frequency response curve and impedance. All these tests guarantee impeccable quality and very limited dispersion between loudspeakers.

Before

After

SPEAKER ASSEMBLY

The parts are manufactured and assembled with millimetric precision, a true work of goldsmith to offer impeccable finish and acoustics.

Optimizing vibration behavior

CABINETRY FOR SOUND

An intensive study of vibration phenomena was carried out to ensure the cabinet's rigidity in the face of the vibrations generated by the speakers.

Measurements were taken using a laser-sensor accelerometer to highlight and model wall deformation, so that reinforcements could be placed at optimal locations. This process not only eliminated virtually all vibrations, but also controlled the deformation of the cabinetry.

Before

After

CAREFUL MONITORING

The anechoic chamber installed at the heart of the factory is a constant guarantee of quality.

Every speaker manufactured is subjected to strict acoustic controls. Numerous tests are carried out to define the best curves and select the best-performing materials.

TRIANGLE Acoustic Signature

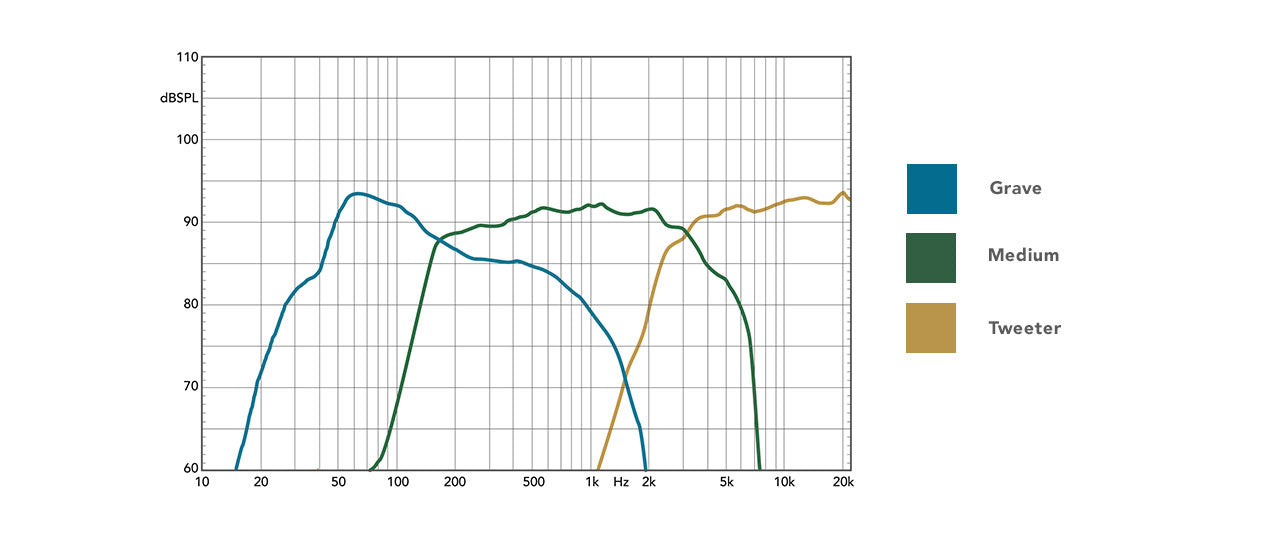

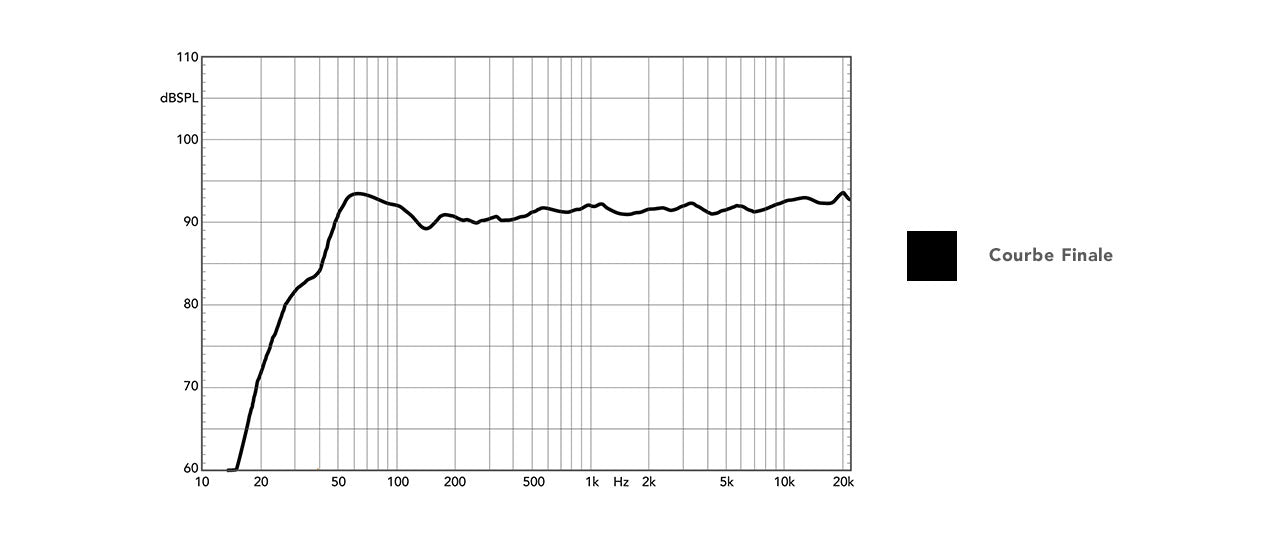

FILTERING

This process adjusts the sound band allocated to each loudspeaker to deliver a precise, coherent sound. It defines the balance and acoustic signature of a loudspeaker. It is entrusted to our most experienced acousticians so that each loudspeaker retains the dynamic, precise and lively identity so dear to TRIANGLE.

Before

After